Cookies help us deliver our services. By using our services, you agree to our use of cookies.

Learn more

Manufacturing

| OUR FACTORY Since 1978, we have been proud of being one of the |

|

|

|

|

||

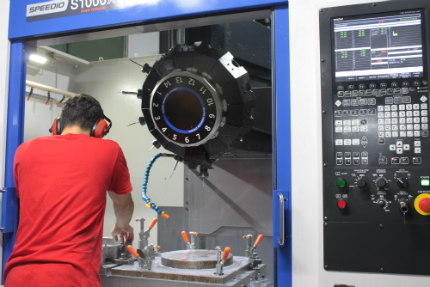

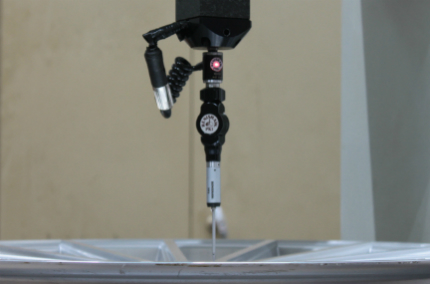

| CNC PROCESSİNG Ford Special production forged wheel factories employs 22 cnc machines with the latest technology to produce the world's finest wheels. In the respect, each combination has the best combination of the most precise and smooth forging wheel processing. |

DEPARTMENT OF DELIVERY The finishing department is responsible for the preparation of smooth forging surfaces by performing extremely rigorous work with manuel workmanship to prepare special rims. Brushed or polished veneered rims provide a mysterious and exotic look thanks to trained masters. |

PAINT DEPARTMENT Forged has a wide range of paint options such as custom-made forging wheels, brushed surface powder coating and precision parting. Kmforged is making paint using the world's best equipment in the paint sector. Forged has 100% full control of forged rims as it prepares every phase of the rim in its own production. In this respect all our wheels are manufactured with extraordinary quality and precision. |

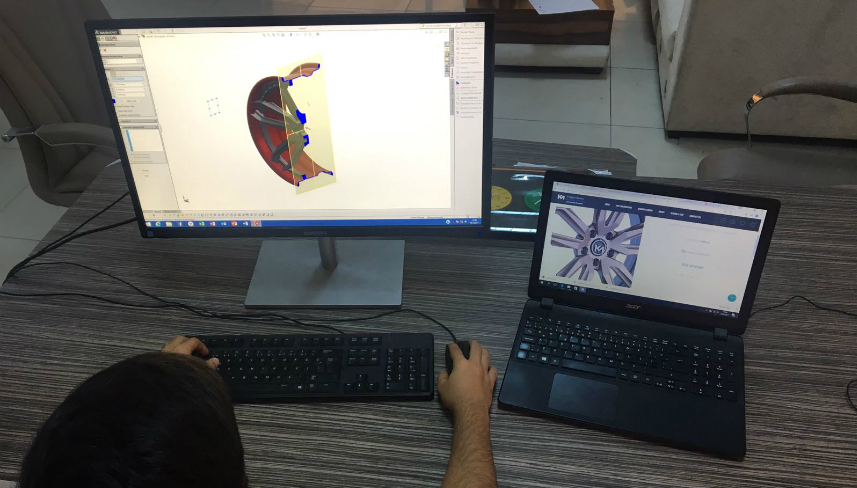

| ENGINEERING The special forged performance wheels are designed with measurements and analyzes from more than 100 data points for ultralight and much more robustness. The desired special rims are modeled in CAD programs for each wheel and every car brand, ensuring SAE and TUV compatibility by maximizing safety. All wheel models are tested in virtual wheel analyzes (FEA). Forged engineering uses Solidworks, Unigraphics, Autocad, Ansys, Workbench and Powermill programs for product design and analysis. |

|

|

|

|

DESIGN Forged does not desing custom forging wheels to reduce cnc workmanship time, making it straightforward for manufacturing ease. Every detail is thought very thin on all my forged wheels. The design process is carried out in accordance with customer requirements and blank spaces in the market. |

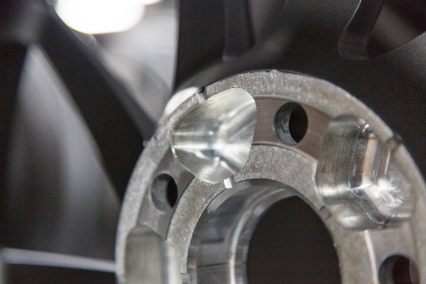

VEHICLE CUSTOM ENGINEERING AND MEASUREMENTS All of our special wheels are carefully examined to ensure that your car is precisely superior to the OEM wheels in accordance with the center diameter mounting surface, ET offset values and braking system, to minimize the weight of the gauge wheel, to maximize the vehicle's wheel dimensions help. |

| PRODUCTION Kmforged has developed a machining process with wide range of machinery and expert staff in every process to produce the best quality and precision wheels for forged rims in the industry and has not hesitated offer these steps to you. |

|

|

|

|

||

| MATERIAL Kmforged wheels are manufactured from magnesium and titanium alloy aluminum used in the 6061-T6 heat- treated aerospace industry to pass through performance and the toughest tests. In this case, our forged wheels are improved versions of orginal OEM automobile wheels. |

PROGRAMMING Each wheel is designed in CAD programs and then processed in CNC using computer aided manufacturing software (CAM) programs. Forged uses the world's most advanced CAM program the Powermill program. |

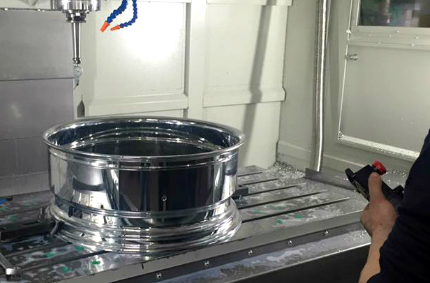

CNC TURNING The first operation in machining for the production of forged rims is the cnc turning. Forged has both vertical turning and high speed CNC turning. This gives us more precise processing and brighter surfaces. At this stage, more than half of the rough material is processed and chip is removed. |

|

|

|

||

| CNC MILLING After turning, the cnc miling operations are processed according to the CAM program sequence to provide the desired shapes. Forged uses diamond- tipped pliers to provide the smoothest surface. In this respect, CNC machines are at the highest level of precision. |

PALLIATION After all cnc operations and face design have been completed (FEA), it is the process of discharging excess weights from the rear of the rim surface in accordance with their analysis. Extra lightness between 5% and %10 is achieved. |

MY BRANDS The forged rims allow the rim with the order number to be the original of the rim, or the whole storage of the rim can be stored for a lifetime. Because the serial numbers are registered with your name, you may be asked to provide information such as stolen, you will certainly not be a victim. |

|

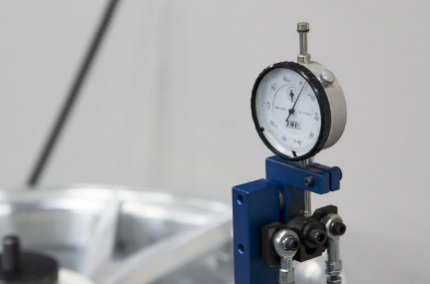

QUALITY CONTROL Quality requires precise control. Forged offers excellence on all its wheels, so each dimension is tested with individual quality control devices. The most critical measurement here is that the rotating wheel has full roundness. Forged performance gives you wonders. |

|